Breezy launches AI-powered Industry 5.0 robotic line in Poland

Breezy, a subsidiary of the ASBIS Group specializing in the refurbishment and remarketing of second-life IT products, has unveiled a cutting-edge facility in Raszyn (just outside Warsaw), Poland. This state-of-the-art plant uses advanced artificial intelligence (AI) and robotic solutions to efficiently grade and upgrade pre-owned smartphones. The innovative production line is capable of grading up…

Breezy, a subsidiary of the ASBIS Group specializing in the refurbishment and remarketing of second-life IT products, has unveiled a cutting-edge facility in Raszyn (just outside Warsaw), Poland. This state-of-the-art plant uses advanced artificial intelligence (AI) and robotic solutions to efficiently grade and upgrade pre-owned smartphones. The innovative production line is capable of grading up to one million devices and refurbishing up to 320,000 smartphones per year. Taking up just 600 m2 of space, the new facilities enhance Breezy’s ability to deliver high-precision diagnostics and process pre-owned devices.

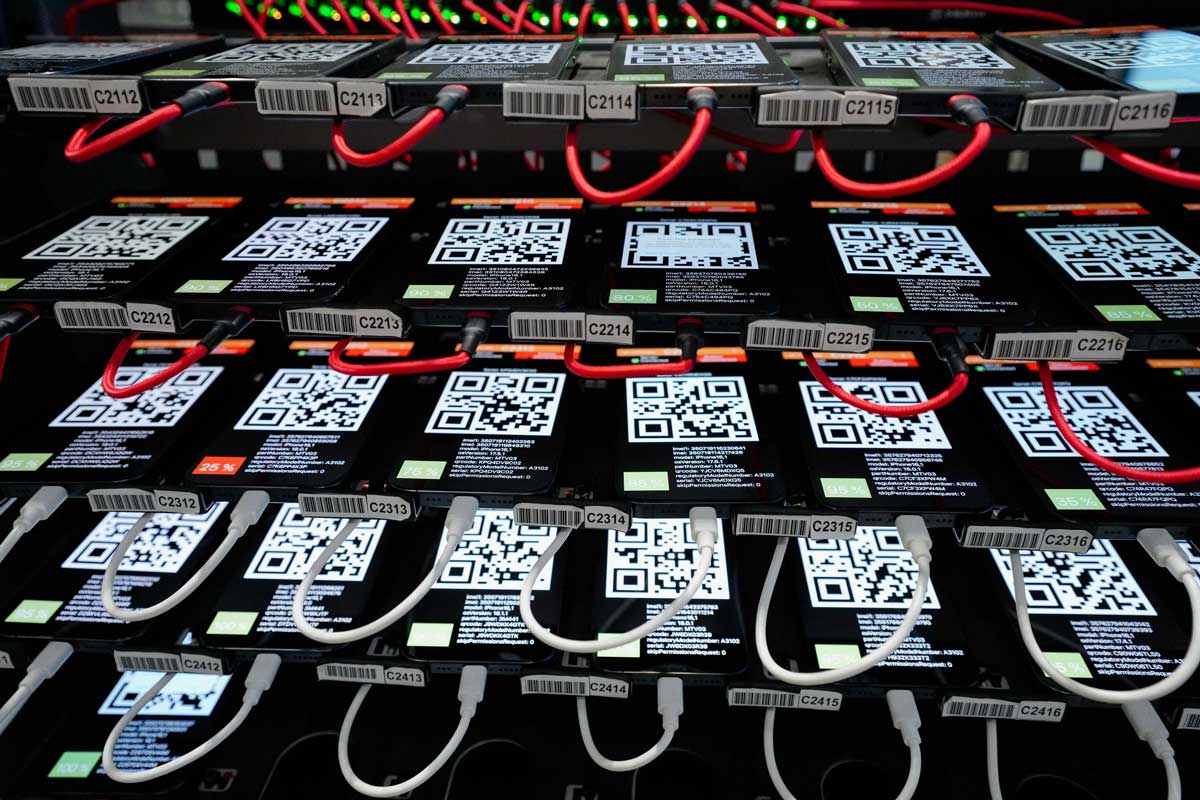

The grading and sorting line features 18 robotic workstations and requires only 4 human operators per shift. All devices received at the facility first pass through a DECANT station, where product models, IMEI, and serial numbers are automatically detected. The station also erases data in compliance with NIST-800-88 standards; charges the phone’s battery; uploads the diagnostic application; connects to the local network; and transfers diagnostic data to the device management database.

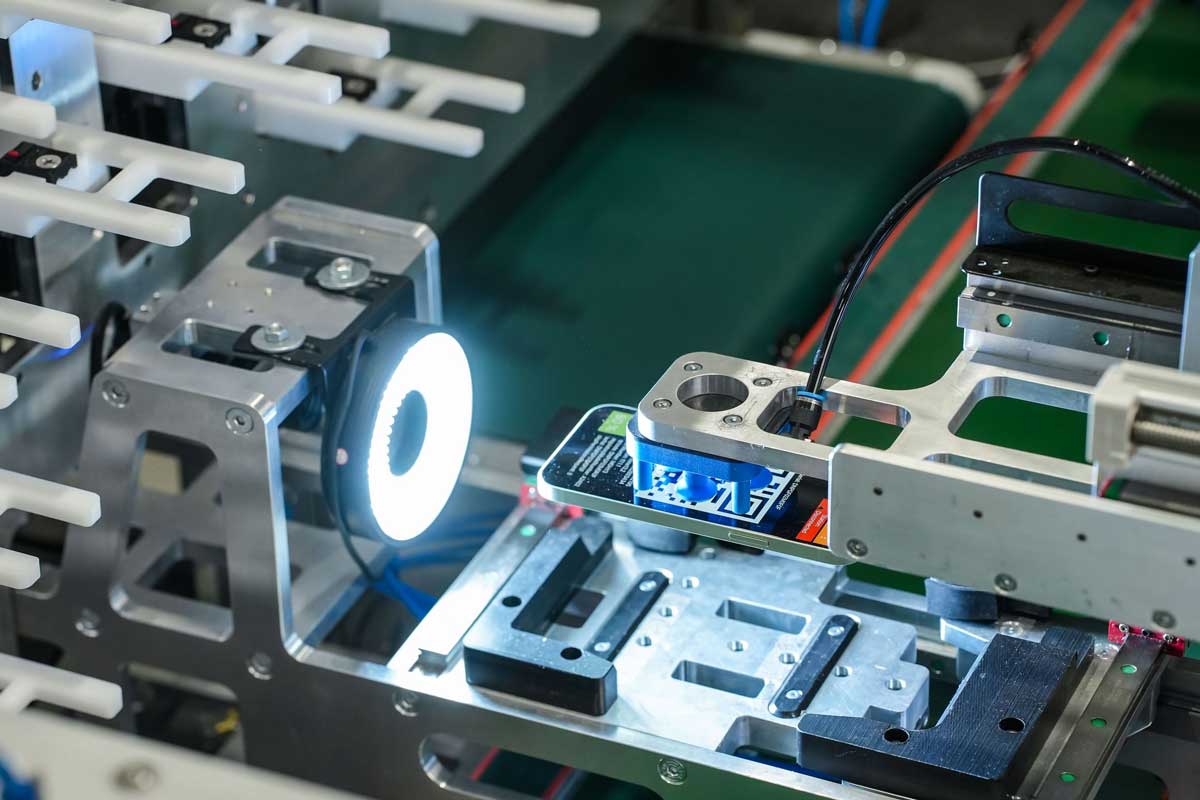

After being cleaned and loaded onto a buffer conveyor, devices undergo a series of automated inspections. The process begins with AI-powered visual detection to identify scratches on the screen, as well as on the entire body of the smartphone. This is followed by robotic audio tests in a soundproof chamber, covering low, mid, and high frequencies for precise results. Further evaluations include automated tests for touch functionality, buttons, and cameras. The sorting station then determines if a device is ready for cosmetic refurbishment or needs polishing, a battery change, or electronic repairs.

Next, an automated photography booth takes high-quality images of the smartphone’s body from six angles. These photos are instantly uploaded to the device’s digital portfolio to provide transparency for buyers.

Each device is subsequently moved by conveyor belt to a robotic station for data erasure and power-off, followed by packing in individual protective, eco-friendly foils, and labeling. In the outbound warehouse, the devices are loaded into retail gift boxes or bulk master cartons, with labeling tailored to their destination markets.

Breezy’s new facility in Raszyn exemplifies the future of sustainable re-commerce. By integrating advanced AI and robotics, the company is setting new standards in efficiency and precision for the refurbishment of pre-owned smartphones.

Serhei Kostevitch, CEO of ASBIS Group, commented: “I am pleased to witness the outcome of the collaborative efforts between Breezy’s re-commerce experts and the ASBIS Robotic Solutions (AROS) engineering team. Their partnership has resulted in the establishment of a cutting-edge, ‘Industry 5.0’ automated production facility. This scalable and cost-effective solution ensures consistent diagnostics and can be replicated cost-effectively across multiple markets.”

INDUSTRY 5.0 – DEFINING THE NEW APPROACH TO SUSTAINABILITY AND RESILIENCE

- A HUMAN-CENTRIC ENTERPRISE

Industry 5.0 standards focus on the synergy between humans and robotic systems. At Breezy’s facility, repetitive and physically demanding tasks are managed by collaborative robots, automated lines, and AI solutions. This allows employees to concentrate on high-value tasks, such as repairs and customer interactions, promoting their well-being and sustainable performance.

Emil Oklinski, Director of Breezy Poland, commented: “AI and robotic solutions enable 24/7 operations, scaling grading and upgrading to 1,000,000 units per year with improved accuracy. Breezy is also prepared to offer devicegrading as a service, ensuring compliance with a range of data protection standards.”

- SUSTAINABILITY

Industry 5.0 enterprises leverage technology to benefit society, the environment, and the circular economy. Breezy’s new production line exemplifies this principle by making technology more accessible, reducing electronic waste, and cutting CO2 emissions. By the end of 2024, Breezy had given a second life to over 300,000 smartphones, reducing CO2equivalent emissions by more than 20,000 tons.

- RESILIENCE

Industry 5.0 solutions bolster business resilience against modern challenges. Breezy, a leader in pre-owned device remarketing, prioritizes offering the best prices to customers. Enhanced operational efficiency—achieved through error-free grading, reduced labor costs, and faster processing times—enables Breezy to maintain competitive pricing while ensuring profitability. Additionally, providing comprehensive product information builds customer trust, addressing a key industry challenge.

Andrii Kosar, General Manager of Breezy, noted: “One of Breezy’s core values is transparency, which we achieve by providing customers with maximum product information before they even open the box of a refurbished device. Thanks to automated photography, we capture high-quality images from six angles, revealing the finest exterior details. Additionally, each product carries a QR code linking to a certification report detailing over 55 testing parameters. Our automated grading system enables this unique level of transparency for our customers and will markedly improve our scalability, sustainability, and time-to-market..”

International

International  Ukraine

Ukraine  Poland

Poland  Georgia

Georgia  Kazakhstan

Kazakhstan  Cyprus

Cyprus  Azerbaijan

Azerbaijan  Moldova

Moldova